Product description

Model: MOU 1

The grinding machine is a special grinding machine used for processing magnetic tile. The various surfaces of the magnetic tile are processed by the grinding method. The operator only needs to put the product in order to the conveyor belt. Automatic feed material, continuous grinding, to increase efficiency and improve the accuracy and reduce the labor intensity of, especially in mass production, plummeted 70% of the cost of production is processing magnetic tile project selection.

Main technical parameters

Head lift travelSpindlespeed

| Item parameters | parameter |

| Device dimensions (l * w * h) (mm) | 1600×900×1700(mm) |

| Spindle motor power | 4KW |

| Emery wheel diameter | Φ180~Φ220 |

| Magnetic tile arc width | ≤32mm |

| Feed motor power | 2-20m/min |

| Head lift travel | 70mm |

| Axial travel of grinding head | 40mm |

| Spindlespeed | 4000 |

Grinding precision | ±0.015 |

Product surface roughness | Ra0.8 |

Grinding wheel type | The diamond grinding wheel, resin grinding wheel is optional, optional grain number |

Conveyor belt size (perimeter * width) | 1400×105(mm) |

Equipment weight | 1000KG |

* technology innovation and improvement, parameters will be changed, with the actual date of the latest data!

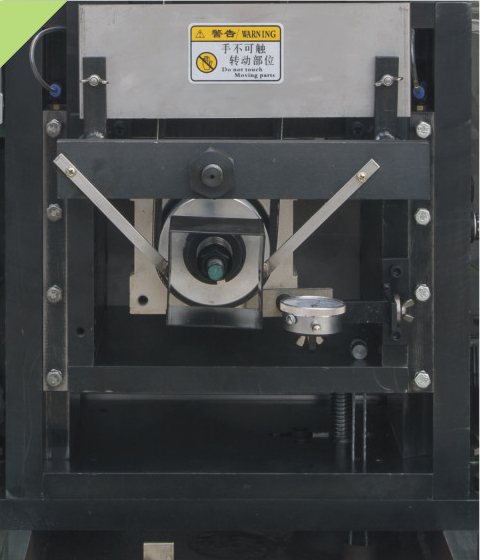

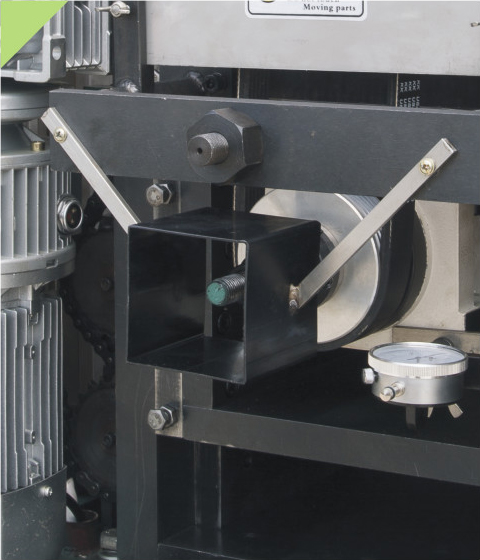

High rigidity of grinding wheel spindle. Double guide rail structure has been the national patent (Patent No.: ZL2015201025162.7) Advanced structure, super high precision, super high strength |

The grinding wheel spindle can not be shut down for the axial dimension adjustment (product symmetrical adjustment), Is the grinding wheel R center aligned with the center of the product. Convenient size adjustment |

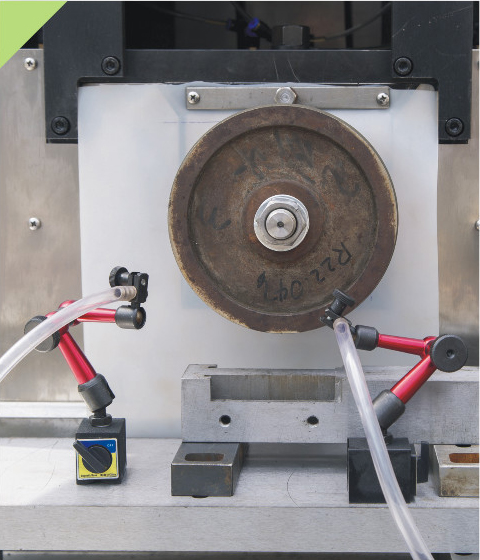

High speed forming grinding, grinding wheel line speed of up to 50m/s to 30m/s (root According to user requirements), grinding efficiency is high, the product size consistency is good, the grinding wheel life Long life. Adjust the speed according to the request |

Pressing wheel up and down synchronous rotation (can be stepless speed control) to make the product conveying uniform, Can avoid the damage caused by products. High quality stability |

中文版

中文版 English

English Tel: 0574-88333886

Tel: 0574-88333886