Product description

Model: TAO 3

Multi station hole drilling machine is used for processing magnetic materials, semiconductor materials, glass and other brittle hard materials.

Main technical parameters

Taper of spindle and tool holder

| Item parameters | parameter |

| Swing over bed | Φ110 |

| Maximum stroke (mm) | 180 |

| Spindle hole diameter tube | Φ20 |

| 38° | |

| Number of spindles (tool holder) | 3 |

| rpm | 3000r/min |

| Spindle motor power | 1.5KW,2800r/min |

| Power | 380V±10%,50HZ |

Device dimensions (l * w * h) (mm) | 1000*800*1570 |

Weight of equipment (KG) | 390 |

Cooling pump | 380V 40W |

* technology innovation and improvement, parameters will be changed, with the actual date of the latest data!

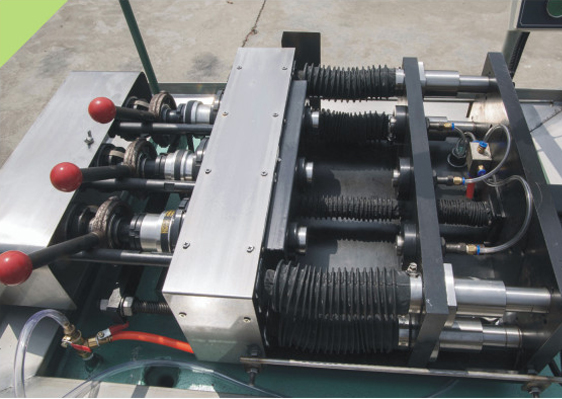

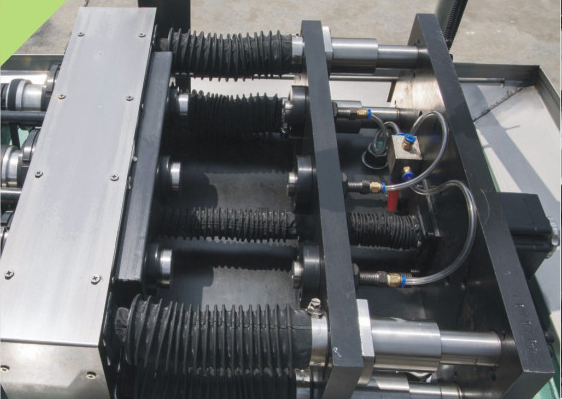

Horizontal spindle structure. Precision angular contact ball bearing for spindle support. The spindle has high precision, strong rigidity, easy to adjust and long service life. |

Three axes synchronous straight line processing, once completed 3 parts processing, compared to the ordinary machine tool benefit to carry on the High more than 3 times, greatly reducing the cost of processing, in the same conditions also improve colleagues Utilization rate of plant unit area. |

The transmission part adopts Taiwan high precision ball screw, and the outer sleeve telescopic protective cover is used for dust proof imitation, To ensure the durability of the screw rod precision. The screw rod is arranged in the middle of the guide rail, the knife base stress Uniform, smooth operation, so that the machine is more accurate. |

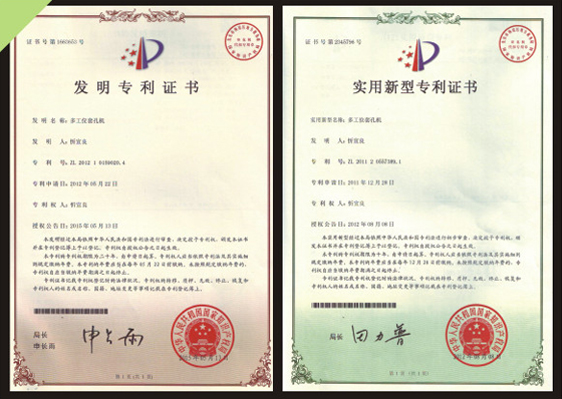

The company invented the multi station sets of holes, and the first to push the national market, has been issued by the state The patent (ZL 201210159020.4) and ZL (patent 201120557389.1) |

中文版

中文版 English

English Tel: 0574-88333886

Tel: 0574-88333886